1.Introduction

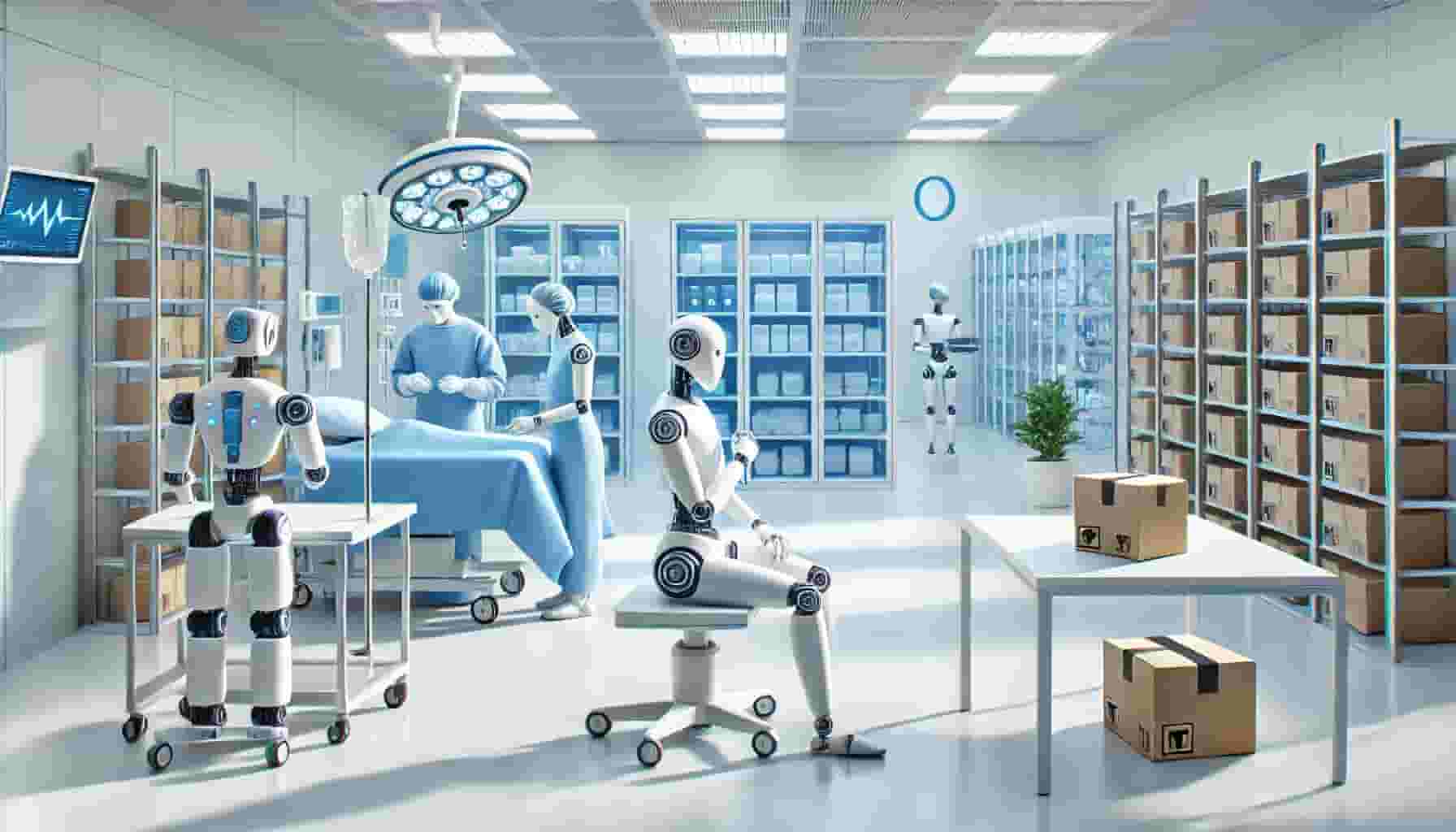

Think about a world where machines don’t just follow instructions but actually think and adapt. That’s what Artificial Intelligence (AI) brings to robotics! AI helps robots process information, make decisions, and even predict what might happen next. This technology has completely changed how robots work. Today, robots powered by AI can perform tasks like helping in surgeries, moving goods in warehouses, or even taking care of crops on a farm.

Many industries are now using this powerful mix of AI and robotics. Hospitals use robots to assist doctors with precise surgeries. Farmers use them to monitor crops and improve harvests. Factories rely on them to speed up production lines. AI-powered robots aren’t just ideas for the future—they’re already making a big difference in the world around us.

In this blog, we’ll explore how AI is transforming robotics, the latest trends in this field, some challenges that need solving, and what the future might hold. Whether you’re a tech fan, a business owner, or just curious about how robots are changing our lives, this guide will give you clear and easy-to-understand insights. Let’s dive into the exciting world of AI in robotics!

Table of Contents

- Historical Context: The Evolution of AI in Robotics

- Core Technologies Powering AI in Robotics

- Applications of AI-Powered Robotics Across Industries

- Challenges and Ethical Considerations

- Best Practices for Implementing AI in Robotics

- Emerging Trends and Future Predictions

- Underrepresented Opportunities in AI-Powered Robotics

- Practical Advice for Readers

- Conclusion

2.Historical Context: The Evolution of AI in Robotics

The Birth of Robotics

The journey of robotics began long before the advent of AI, with early robots designed to perform repetitive tasks. These robots were basic machines, following fixed instructions to complete simple jobs. Think of assembly lines in factories during the mid-20th century—robots helped streamline production, but they couldn’t adapt or think for themselves.

One of the earliest examples is the Unimate, the first industrial robot introduced in 1961. It was used in automobile manufacturing to handle tasks like welding and stacking. While groundbreaking at the time, robots like Unimate lacked any decision-making capabilities and operated solely on pre-programmed instructions.1

2.2 Introduction of AI to Robotics

The real game-changer came when Artificial Intelligence entered the picture. In the 1980s and 1990s, researchers began integrating AI into robotics to make machines more intelligent and adaptable. This period marked several key milestones:

- Neural Networks: Early AI systems mimicked the human brain’s ability to process information, laying the foundation for smarter robots.2

- Computer Vision: Robots gained the ability to “see” and understand their environment, opening up new possibilities for interaction and navigation.3

- Machine Learning: By using algorithms that could learn from data, robots started improving their performance over time.4

An example of this shift was the Stanford Cart, a robot developed in the 1970s, which used rudimentary AI to navigate obstacles. Although slow and basic, it was a major step forward in teaching robots to “think” beyond pre-programmed tasks.5

2.3 Transition to Intelligent Robotics

The 21st century brought a major transformation: the shift from automation to autonomy. Robots were no longer just tools; they became intelligent systems capable of making decisions without constant human input. This leap was made possible by advancements like:

- AI-powered Autonomous Systems: Robots like self-driving cars, drones, and robotic vacuum cleaners operate in unstructured environments, learning and adapting as they go.6

- Collaborative Robots (Cobots): These robots work alongside humans, sharing tasks in manufacturing, healthcare, and more.7

- Sophisticated Algorithms: With deep learning and reinforcement learning, robots started mastering complex tasks, from playing chess to performing surgeries.

One standout example is Boston Dynamics’ robots, which demonstrate extraordinary balance, agility, and adaptability. Robots like Spot and Atlas showcase how far robotics has come from the days of simple assembly-line machines.

Timeline of Key Advancements in AI and Robotics

1961: The First Industrial Robot – Unimate

Unimate, created by George Devol and Joseph Engelberger, was the world’s first industrial robot. It was introduced in a General Motors factory to handle tasks like welding and stacking. Although it couldn’t think or adapt, Unimate was a groundbreaking step in using robots to assist humans in industrial work. It laid the foundation for robotics in factories and beyond.8

1970s: Robots Start to “See” and Learn

The 1970s brought two major advancements in robotics: neural networks and computer vision. Neural networks helped robots process information in a way similar to the human brain, while computer vision allowed robots to interpret images. One famous example is the Stanford Cart, a robot that could navigate around obstacles. It wasn’t fast or efficient, but it showed the potential of robots to think beyond basic programming.9

1980s-1990s: Smarter Robots with AI

In the 1980s and 1990s, robotics saw a leap forward with the integration of artificial intelligence. Machine learning allowed robots to improve their performance by learning from data. For example, MIT developed robotic arms that could adapt to tasks, making them much more efficient than earlier models. This era showed the first signs of robots becoming more intelligent and useful in dynamic environments.10

2000s: Robots Working Independently

By the 2000s, robots had become more autonomous, meaning they could perform tasks without constant human input. The Roomba, an AI-powered vacuum cleaner, became a popular example of robots entering everyday homes. In factories, collaborative robots (cobots) were introduced. These robots could safely work alongside humans, sharing tasks and boosting productivity.11

2010s and Beyond: Intelligent and Adaptive Robots

The past decade has been a game-changer for robotics. Deep learning allowed robots to analyze large amounts of data and make smarter decisions. Companies like Boston Dynamics introduced robots like Spot (a robotic dog) and Atlas (a humanoid robot) that can handle rough terrains, perform acrobatic moves, and even assist in rescue missions. AI-powered self-driving cars and drones also became part of our daily lives, showing the real potential of robotics in transportation and logistics.12

This timeline shows how robots have evolved from simple machines to intelligent systems. Each step forward has made robots more capable, useful, and integrated into our daily lives.

3.Core Technologies Powering AI in Robotics

3.1 Machine Learning and Deep Learning

Machine learning and deep learning are the driving forces behind the intelligence of modern robots. These technologies allow robots to learn from data, identify patterns, and improve their performance over time.

- Machine Learning: This involves training robots to recognize patterns and make decisions based on past experiences. For example, a warehouse robot can learn to optimize its path by analyzing previous routes.13

- Deep Learning: A subset of machine learning, deep learning uses neural networks that mimic the human brain. It enables robots to process complex data, such as identifying objects or understanding speech.14

Role in Robotics: These technologies make robots smarter and more adaptive. For instance, autonomous vehicles use deep learning to recognize road signs, detect obstacles, and navigate safely.

Scalability Tip: Robots can be trained in simulated environments using machine learning, reducing the time and cost of real-world testing.15

3.2 Computer Vision and Natural Language Processing (NLP)

Robots equipped with computer vision and NLP can better understand and interact with their surroundings and humans.

- Computer Vision: This technology enables robots to “see” and interpret visual data, such as images and videos. Robots can use computer vision for object recognition, facial detection, and even quality control in manufacturing.16

- Natural Language Processing (NLP): NLP allows robots to understand and respond to human language. This is particularly useful in customer service robots, virtual assistants, and healthcare robots.17

Role in Robotics: These capabilities enhance human-robot interaction and enable robots to operate in dynamic environments. For example, drones with computer vision can identify and map disaster-stricken areas, while service robots with NLP can assist customers in retail settings.

Scalability Tip: Integrating both technologies creates versatile robots that can adapt to different tasks, from simple navigation to complex human interaction.18

3.3 Edge Computing and Cloud AI

The combination of edge computing and cloud AI provides robots with the ability to process data efficiently and operate in real time.

- Edge Computing: Involves processing data locally on the robot itself, reducing latency and enabling quick decision-making. For instance, a robotic vacuum can adjust its cleaning path instantly when it detects obstacles.19

- Cloud AI: Allows robots to access powerful AI models and large datasets stored in the cloud. This is particularly useful for tasks requiring significant computational resources, such as advanced image recognition.20

Role in Robotics: Together, these technologies ensure that robots are both fast and resource-efficient. Edge computing handles real-time tasks, while cloud AI manages data-intensive processes.

Scalability Tip: Hybrid models (combining edge and cloud computing) provide the best of both worlds, ensuring scalability while minimizing costs. For example, an autonomous delivery robot can process navigation in real time using edge computing while accessing updated traffic data from the cloud.

3.4 IoT and 5G in Robotics

The Internet of Things (IoT) and 5G connectivity are essential for creating interconnected and highly responsive robotic systems.

- IoT: Enables robots to communicate with other devices and systems. For example, robots in a smart factory can coordinate with IoT sensors to streamline production.

- 5G: Provides ultra-fast and low-latency connectivity, allowing robots to transmit and receive data almost instantly. This is critical for applications like autonomous drones and remote-controlled robots in hazardous environments.

Role in Robotics: IoT ensures seamless communication, while 5G enhances the speed and reliability of these interactions. This combination is essential for robots to operate effectively in interconnected environments. Scalability Tip: By leveraging IoT and 5G, businesses can deploy fleets of robots that communicate and coordinate in real time, significantly improving efficiency and scalability21.

4.Applications of AI-Powered Robotics Across Industries

AI-powered robots are transforming industries by making tasks faster, safer, and more efficient. Let’s explore how different industries are using these smart machines to solve problems and create new opportunities.

4.1 Healthcare

Robots in healthcare are saving lives and improving patient care every day.

- Surgical Robots: AI-powered robots like the da Vinci Surgical System assist doctors in performing delicate surgeries with precision. These robots reduce risks, minimize recovery times, and improve patient outcomes.

- Diagnostics: Robots equipped with AI help analyze medical data to identify diseases early. For instance, AI-powered imaging tools can detect cancer more accurately than traditional methods.

- Patient Care: Robots are being used to assist patients, especially the elderly, by helping with tasks like medication reminders and mobility.

Measurable Benefits: Surgical robots have reduced post-surgery complications, while diagnostic robots have improved accuracy in detecting diseases by up to 90%.

Success Story: In Japan, robots like PARO are used in therapy for elderly patients, helping them combat loneliness and stress.

4.2 Manufacturing

Manufacturing has been one of the earliest adopters of AI-powered robotics, and the results are impressive.

- Precision Assembly: Robots are used to assemble tiny components in electronics or complex machinery in vehicles, ensuring consistency and precision.

- Quality Control: AI helps robots identify defects in products during manufacturing, improving quality assurance.

- Efficiency Gains: Robots handle repetitive tasks like welding and painting, freeing up human workers for more skilled jobs.

Measurable Benefits: Factories using AI robots report a 20-30% increase in productivity and significant reductions in waste.

Success Story: Companies like Tesla use robots for car assembly, achieving faster production while maintaining high-quality standards.

4.3 Agriculture

AI-powered robots are helping farmers work smarter, not harder.

- Harvesting: Robots like the Agrobot are used to pick fruits and vegetables with care, ensuring minimal damage.

- Crop Monitoring: AI-powered drones and robots analyze crop health, soil quality, and pest activity to provide real-time insights.

- Resource Optimization: Robots help in tasks like precision spraying, reducing water and pesticide usage.

Measurable Benefits: Farmers using AI robots have seen up to 50% increases in crop yields and significant cost savings on resources.

Success Story: In the Netherlands, robots in greenhouses monitor and care for plants, leading to record-breaking tomato harvests.

4.4 Logistics and Supply Chain

The logistics industry is benefiting greatly from AI-driven automation.

- Autonomous Delivery Robots: Robots like those from Starship Technologies deliver packages directly to customers, reducing delivery times and costs.

- Warehouse Optimization: AI-powered robots, such as those used by Amazon, sort, pack, and move goods within warehouses efficiently.

Measurable Benefits: Warehouses using robots have improved order fulfillment rates by up to 70%.

Success Story: DHL uses AI robots to optimize their supply chain, cutting operational costs while improving accuracy and speed.

4.5 Customer Service and Retail

Robots in customer service are enhancing how businesses interact with people.

- AI Chatbots: Virtual assistants like ChatGPT help customers solve problems, answer questions, and make decisions, 24/7.

- Humanoid Robots: Robots like Pepper are used in stores to greet customers, provide product information, and even process payments.

Measurable Benefits: Retailers using robots report better customer satisfaction and a 20% boost in sales.

Success Story: In South Korea, robots in shopping malls help customers find products, creating a unique and engaging shopping experience.

5.Challenges and Ethical Considerations

As exciting as AI-powered robotics is, it’s not without challenges. From technical hurdles to ethical dilemmas, understanding these issues is key to creating a future where robots benefit everyone. Let’s explore some of the biggest concerns and how we can address them.

5.1 Technical Challenges

AI and robotics require advanced technology, and building and using these systems can be tricky. Here are some common technical challenges:

- High Costs: Developing and deploying AI-powered robots is expensive. Companies must invest in hardware, software, and continuous maintenance, which isn’t always affordable, especially for smaller businesses.

- Scalability Issues: Scaling robotic solutions to larger operations can be complex. For example, robots might work perfectly in a test setting but face challenges when applied to bigger, real-world environments.

- Integration Complexity: Integrating AI robots with existing systems, like manufacturing lines or warehouse operations, can be a logistical headache.

Strategies to Address These Challenges:

- Cost Management: Encourage the use of modular robots that can be customized for specific tasks, reducing initial investment costs.

- Scalable Models: Use cloud-based AI solutions that allow businesses to scale their robotics operations without overhauling infrastructure.

- Integration Tools: Companies can use advanced APIs and middleware to seamlessly connect robots to existing systems.

5.2 Ethical Implications

Robotics and AI are changing how we work, but they also raise important ethical questions:

- Job Displacement: Robots can take over repetitive or hazardous jobs, but this also means some workers may lose their jobs. This is especially true in industries like manufacturing and logistics.

- AI Bias: AI systems can unintentionally carry biases from the data they’re trained on. For example, a robot designed to assist in hiring could end up favoring certain demographics, leading to unfair outcomes.

Strategies to Address These Challenges:

- Job Transition Support: Companies adopting robotics should invest in upskilling programs to help employees learn new skills and transition to other roles.

- AI Auditing: Regularly audit AI systems to check for and correct biases. Involving diverse teams in development can also minimize bias.

Why Transparency Matters: Open communication about how AI robots work and how decisions are made helps build trust and ensures accountability.

5.3 Privacy and Data Security

AI-powered robots often rely on large amounts of data to function, and this raises serious privacy and security concerns:

- Sensitive Data Use: Robots in healthcare or retail, for example, might handle personal information. Mismanagement of this data could lead to privacy violations.

- Cybersecurity Risks: Robots connected to the internet are vulnerable to hacking, which could compromise safety and functionality.

Strategies to Address These Challenges:

- Strong Data Policies: Ensure that data collected by robots is stored securely, anonymized when possible, and used only for its intended purpose.

- Enhanced Cybersecurity: Invest in robust security measures, like encryption and regular software updates, to protect robots from cyberattacks.

Accountability is Key: Organizations must be clear about how they handle data and ensure they comply with privacy laws like GDPR.

While AI-powered robotics comes with challenges, they can be managed with thoughtful strategies. By addressing technical hurdles, considering ethical implications, and prioritizing data security, businesses can ensure a fair, safe, and efficient use of these powerful technologies. Transparency and accountability will be critical in building trust and maximizing the benefits of robotics for everyone.

6.Best Practices for Implementing AI in Robotics

Using AI-powered robots can bring huge benefits to businesses, but it’s important to approach the process carefully. Following these best practices will help businesses adopt robotics successfully while ensuring safety and efficiency.

6.1 Start Small and Scale Strategically

Jumping straight into large-scale robotics implementation can be risky. It’s smarter to start small and expand gradually.

- Begin with Pilot Projects: Start by testing AI-powered robots in a limited area to identify challenges and improve processes. For example, use one robotic arm on a production line before automating the entire factory.

- Focus on Specific Tasks: Identify jobs where robots can make the biggest difference, such as repetitive or dangerous tasks. This focused approach ensures quick and visible results.

- Scale Gradually: Once the trial is successful, expand step by step. This gives your team time to adapt and prevents major disruptions.

Quick Tip: Use modular robots that can be upgraded or changed to meet new needs.

6.2 Focus on Data Quality and Feedback

Robots rely on data to learn and make decisions, so the quality of that data is crucial.

- Provide Clean, High-Quality Data: If the data is incorrect or incomplete, robots will make mistakes. Always ensure the data used for training and decision-making is accurate.

- Use Feedback Loops: Robots perform better when they learn from their actions. For example, warehouse robots can improve their routes by analyzing real-time feedback.

Quick Tip: Regularly evaluate how robots are performing and update their data and algorithms as needed.

6.3 Ensure Human-Robot Collaboration

Robots often work alongside people, so it’s important to make this collaboration smooth and safe.

- Design User-Friendly Interfaces: Robots should be easy to use, even for people without technical expertise. Simple controls make them more accessible and less intimidating.

- Set Up Safety Measures: Equip robots with sensors to detect and avoid collisions with humans. Collaborative robots (or cobots) are specifically built to work safely alongside people.

- Train Employees: Help employees understand how robots work and how to interact with them. Training reduces fear and builds trust, making the transition smoother.

Quick Tip: Have a team or supervisor monitor human-robot interactions to address any issues and ensure safety.

7.Emerging Trends and Future Predictions

AI-powered robotics is advancing rapidly, with exciting trends shaping the future. Let’s explore what’s on the horizon and how robots could transform our lives in the next decade.

7.1 Swarm Robotics

Swarm robotics is inspired by nature, where creatures like bees or ants work together to accomplish tasks. Now, AI is helping robots do the same.

- How It Works: Swarm robotics uses groups of robots that communicate and collaborate to complete tasks. With AI, these robots coordinate their actions, making teamwork more efficient.

- Examples in Action: In agriculture, drones are already working together to monitor crops or spray fields. In warehouses, groups of robots manage inventory and sort items.

Looking Ahead: In the future, swarm robots will play a big role in disaster response. Imagine a team of robots searching through rubble or delivering supplies during emergencies. Experts predict AI advancements will make these robot teams smarter and more efficient.

7.2 AI and Quantum Computing in Robotics

Quantum computing is a new technology that could supercharge robotics, helping AI systems process huge amounts of data much faster.

- What It Means for Robots: Quantum-powered AI could help robots analyze complex problems in real time. For example, self-driving cars might use quantum AI to calculate millions of possible traffic scenarios instantly, making them safer and more reliable.

- What’s Happening Now: Companies like IBM and Google are leading the way in quantum computing research. Though still in development, this technology could soon help robots in healthcare, logistics, and more.

Looking Ahead: Over the next decade, quantum computing could help robots solve problems we can’t handle today. Experts believe it will unlock new possibilities, like global supply chain optimization or advanced medical procedures.

7.3 Robots in Disaster Response

AI-powered robots are becoming essential in emergencies, where speed and precision are critical.

- Search and Rescue Robots: Robots with AI and sensors can locate survivors in collapsed buildings or dangerous areas. Drones can map disaster zones and deliver supplies to hard-to-reach places.

- Helping in Crises: Robots are already being used to provide medical aid, food, and water during disasters like floods or earthquakes.

Real-World Examples: In Australia, drones were used during the bushfires to track flames and assist rescue teams. In Japan, robotic dogs with cameras helped find survivors after earthquakes.

Looking Ahead: The next generation of disaster response robots will be faster, more reliable, and capable of working in extreme conditions. Experts believe they’ll become a standard tool for saving lives worldwide.

8.Underrepresented Opportunities in AI-Powered Robotics

While AI-powered robotics is transforming industries, some opportunities remain underexplored. Let’s dive into areas like sustainability, small business adoption, and education that hold significant potential for growth and innovation.

8.1 Sustainability in Robotics

As robotics continues to evolve, there’s a growing need to focus on eco-friendly designs and sustainable practices.

- Reducing Environmental Impact: AI-powered robots can optimize resource usage in industries like manufacturing and agriculture. For instance, precision farming robots use less water and pesticides, reducing harm to the environment.

- Eco-Friendly Designs: Robotics companies are exploring ways to build robots with sustainable materials and energy-efficient systems. Solar-powered drones and robots with recyclable components are steps in the right direction.

Opportunity for Growth: Sustainability in robotics is still in its early stages, but there’s enormous potential for businesses to lead the way in creating greener, more eco-conscious robotic systems.

8.2 Small Business Adoption

AI-powered robotics isn’t just for big companies. Small businesses can also benefit, especially with affordable solutions now available.

- Low-Cost Robotics: Startups and small businesses can use affordable robots to automate simple tasks like inventory management, packaging, or customer service. For example, AI chatbots and compact warehouse robots are accessible to smaller operations.

- Boosting Efficiency: With low-cost robots, small businesses can reduce operational costs, improve accuracy, and stay competitive in their markets.

Opportunity for Growth: By offering scalable, affordable robotics solutions, companies can unlock a massive untapped market in small and medium-sized enterprises (SMEs).

8.3 Education and Upskilling

As robotics becomes more common, training the workforce to understand and work with AI-powered robots is essential.

- Training Programs: Universities and online platforms now offer specialized courses in AI and robotics, helping professionals and students gain the skills needed to work with these technologies.

- Upskilling Opportunities: Businesses can invest in employee training to help their workforce adapt to automation. For example, training programs can teach workers how to operate and maintain robots, ensuring a smooth transition to automation.

Opportunity for Growth: Investing in education ensures that both current and future workers are prepared for the robotic revolution, helping businesses and individuals thrive in a changing job market.

9.Practical Advice for Readers

Implementing AI-powered robotics can feel like a big step, but with the right approach, it becomes manageable and rewarding. Here’s some practical advice to help you get started and succeed.

9.Practical Advice for Readers

9.1 Evaluating AI-Robotics Solutions

Before investing in AI-powered robotics, it’s important to evaluate whether the solution meets your needs.

- Define Your Goals: Identify what you want the robots to achieve. Are you looking to increase productivity, reduce costs, or improve safety?

- Key Performance Indicators (KPIs): Use measurable metrics to evaluate the performance of robots. Common KPIs include:

- Accuracy: How well the robot performs tasks without errors.

- Efficiency: The speed at which tasks are completed compared to manual processes.

- Return on Investment (ROI): The financial benefits versus the cost of the robotics solution.

- Downtime: How often the robot requires maintenance or repair.

Quick Tip: Start by comparing multiple robotic solutions to find one that aligns with your goals and budget.

9.2 Building a Successful Implementation Strategy

Deploying AI-powered robotics is more than just buying machines—it requires a clear plan.

- Step 1: Assess Your Needs: Understand which areas of your business can benefit most from automation. Start with tasks that are repetitive, time-consuming, or prone to errors.

- Step 2: Plan the Deployment: Begin with a pilot project. Test the robots in a controlled setting to identify any challenges and gather feedback.

- Step 3: Train Your Team: Provide training to help employees learn how to use and work alongside the robots. A well-trained team ensures smoother operations.

- Step 4: Monitor and Improve: Regularly review the robots’ performance and update their systems as needed to optimize results.

Quick Tip: Break the implementation into smaller phases to minimize disruptions and allow your team to adapt gradually.

9.3 Overcoming Common Barriers

Adopting robotics often comes with challenges, but these can be managed with the right approach.

- Barrier 1: High Costs: Start small and scale up. Consider leasing robots or using modular systems that allow for incremental upgrades.

- Barrier 2: Employee Resistance: Involve your team early in the process. Show them how robots can make their jobs easier and offer upskilling opportunities.

- Barrier 3: Integration Issues: Use middleware and APIs to connect robots to your existing systems seamlessly. Work closely with vendors to ensure compatibility.

Quick Tip: Focus on communication and transparency. Address concerns openly to build trust and reduce resistance to change.

Conclusion

AI in Robotics has come a long way, transforming industries and revolutionizing how we work, live, and solve problems. From assisting surgeons in healthcare to improving productivity in manufacturing, these smart machines are making tasks faster, safer, and more efficient. They’re not just tools of convenience—they’re game-changers shaping the future.

Throughout this guide, we’ve explored the evolution of AI in Robotics, the core technologies driving their capabilities, and their applications across various industries. We’ve also tackled the challenges of implementing robotics and highlighted emerging trends like swarm robotics, quantum computing, and disaster response. These trends demonstrate the limitless potential of robotics to create a positive impact on our world.

While significant progress has been made, there’s still much to explore. By focusing on opportunities in sustainability, small business adoption, and education, businesses and individuals can harness the full potential of robotics. Transparency, accountability, and thoughtful planning will be key to ensuring this technology benefits everyone.

AI in Robotics is no longer just a futuristic concept—it’s a present reality reshaping our world. As this journey continues, the possibilities are endless, and the impact on industries, society, and the planet will only grow.

References:

- https://www.javatpoint.com/robotics-and-artificial-intelligence ↩︎

- https://onlinedegrees.sandiego.edu/application-of-ai-in-robotics/ ↩︎

- https://www.v7labs.com/blog/ai-in-robotics ↩︎

- https://aibusiness.com/verticals/robotics-and-artificial-intelligence-the-role-of-ai-in-robots ↩︎

- https://www.tutorialspoint.com/artificial_intelligence/artificial_intelligence_robotics.htm ↩︎

- https://www.geeksforgeeks.org/artificial-intelligence-in-robotics/ ↩︎

- https://onlinedegrees.sandiego.edu/application-of-ai-in-robotics/ ↩︎

- https://aibusiness.com/verticals/robotics-and-artificial-intelligence-the-role-of-ai-in-robots ↩︎

- https://www.v7labs.com/blog/ai-in-robotics ↩︎

- https://onlinedegrees.sandiego.edu/application-of-ai-in-robotics/ ↩︎

- https://www.geeksforgeeks.org/artificial-intelligence-in-robotics/ ↩︎

- https://www.intel.com/content/www/us/en/robotics/artificial-intelligence-robotics.html ↩︎

- https://www.geeksforgeeks.org/artificial-intelligence-in-robotics/ ↩︎

- https://www.v7labs.com/blog/ai-in-robotics ↩︎

- https://onlinedegrees.sandiego.edu/application-of-ai-in-robotics/ ↩︎

- https://aibusiness.com/verticals/robotics-and-artificial-intelligence-the-role-of-ai-in-robots ↩︎

- https://www.tutorialspoint.com/artificial_intelligence/artificial_intelligence_robotics.htm ↩︎

- https://www.intel.com/content/www/us/en/robotics/artificial-intelligence-robotics.html ↩︎

- https://www.v7labs.com/blog/ai-in-robotics ↩︎

- https://aibusiness.com/verticals/robotics-and-artificial-intelligence-the-role-of-ai-in-robots ↩︎

- https://aibusiness.com/verticals/robotics-and-artificial-intelligence-the-role-of-ai-in-robots ↩︎